Putting Materials to the Test: Discovering the Function of Products Test Labs

Products examination laboratories play a crucial function in making sure the top quality and reliability of various products made use of in markets such as aerospace, construction, and manufacturing. Via a combination of sophisticated methods and customized tools, materials test laboratories are able to evaluate the properties of metals, polymers, compounds, and other products under various problems and stress factors. This write-up will certainly check out the importance of materials screening, the kinds of materials evaluated, testing strategies and devices used, as well as the applications of materials test results.

Value of Materials Testing

Frequently evaluating the top quality of materials is vital in guaranteeing the integrity and safety of items in various industries. Products testing includes subjecting materials to various examinations and experiments to evaluate their mechanical, physical, and chemical buildings.

One of the vital factors why materials testing is crucial is the guarantee of product quality. With strenuous screening, producers can determine any type of problems or weak points in the products made use of for their products.

By subjecting products to different tests, suppliers can establish their toughness, stamina, and resistance to external variables such as warm, stress, or chemicals. Whether it is vehicle components, clinical devices, or building and construction materials, products testing aids in determining any kind of prospective safety and security dangers and developing proper measures to alleviate them.

Sorts Of Products Tested

Different sorts of materials are examined in materials examination labs to examine their mechanical, physical, and chemical residential properties. These materials can include a wide variety of materials, including metals, polymers, porcelains, composites, and even all-natural products such as wood and concrete.

Steels are commonly evaluated as a result of their widespread use in numerous industries. These tests examine residential or commercial properties such as tensile stamina, solidity, and ductility. Polymers, on the other hand, are evaluated to establish their elasticity, thermal stability, and resistance to chemicals. Ceramics are checked out for their brittleness, resistance, and toughness to heats. Compounds, which include two or even more different materials, are assessed to comprehend their general efficiency, consisting of variables like strength, resilience, and versatility.

Natural products like timber are examined to analyze their strength, wetness material, and resistance to decay (materials test lab). Concrete is one more generally checked material, with tests concentrating on its compressive stamina, longevity, and resistance to ecological aspects

In enhancement to these products, materials examination labs additionally assess coverings, paints, adhesives, and numerous other materials made use of in building, production, and other sectors. By subjecting these materials to strenuous testing, designers and scientists can gather useful information to inform product selection, style optimization, and top quality control procedures.

Checking Strategies and Equipment

Checking strategies and equipment play a crucial function in products test laboratories for reviewing the mechanical, physical, and chemical buildings of various materials. These methods and tools are important in making sure the top quality, reliability, and safety of materials utilized in different sectors such as aerospace, automotive, building, and medical.

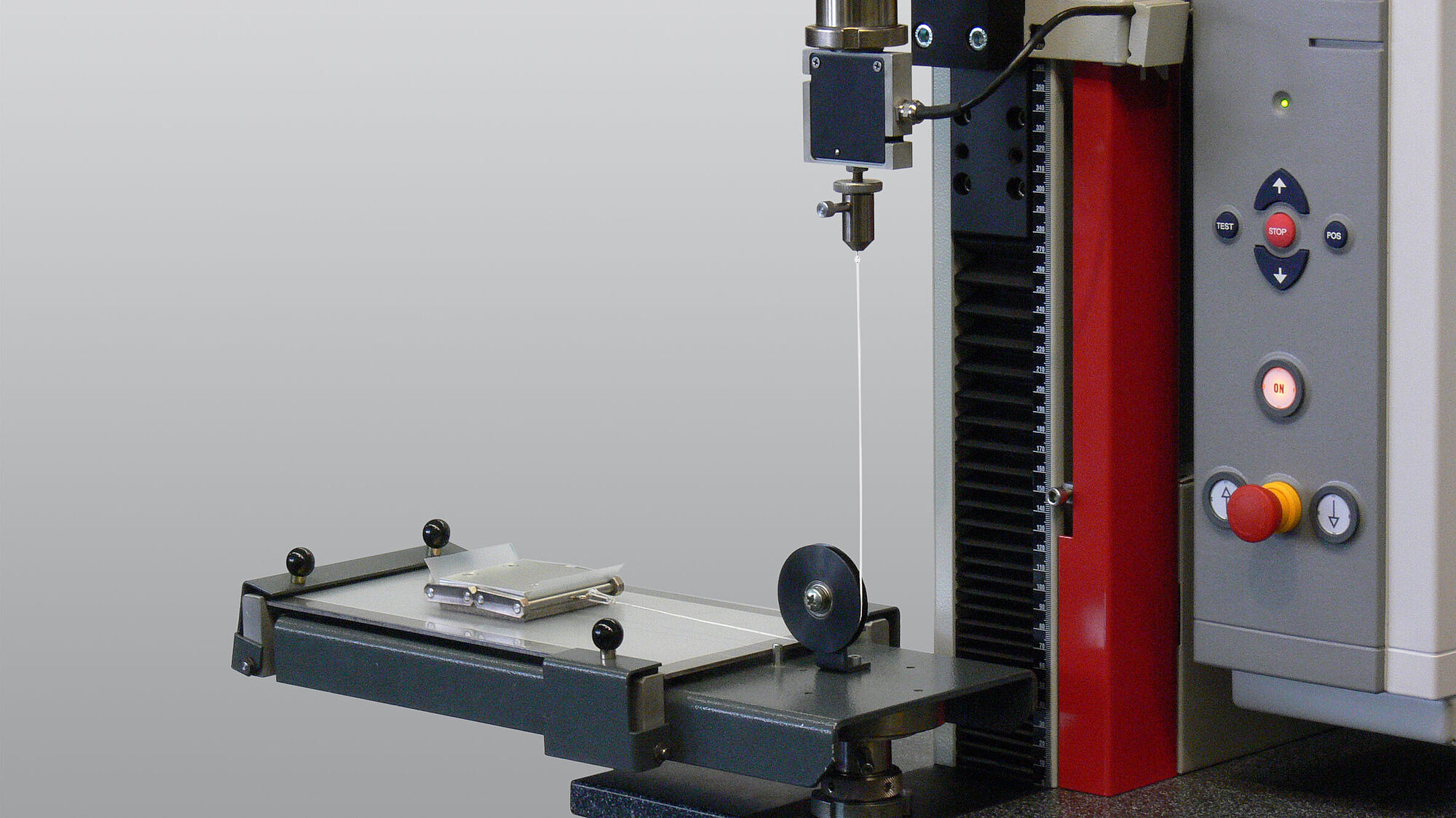

One frequently made use of screening method in products examination laboratories is mechanical screening, which entails subjecting products to various forces or loads to determine their stamina, firmness, ductility, and other mechanical buildings. This is often done using equipment such as universal screening machines, which can use tensile, compressive, and flexing pressures to examine samplings.

Physical screening strategies are likewise utilized to examine buildings such as thickness, thickness, thermal conductivity, and electrical conductivity. Equipment such as density meters, viscometers, thermal conductivity analyzers, and electrical conductivity meters are made use of to execute these examinations precisely.

Chemical testing techniques are used to determine the chemical make-up and pureness of products. Methods such as mass, chromatography, and spectroscopy spectrometry are generally utilized, along with specialized equipment designed for these objectives.

Applications of Materials Test Results

The results of materials evaluating offer useful understandings into the performance and suitability of different materials for specific applications in various industries - materials test lab. These examination results play a crucial role in determining the top quality, durability, and safety of products made use of in producing processes

One of the key applications of products examination results remains in the field of construction. Engineers and engineers rely upon these results to pick proper materials for building frameworks, such as bridges, high-rises, and property buildings. By conducting examinations on materials like steel, concrete, and wood, they can make certain that these products meet the called for requirements and can endure numerous ecological conditions.

In the aerospace sector, materials examination results are important in establishing the suitability of products for aircraft components. By subjecting products to rigorous screening, engineers can examine their mechanical residential properties, resistance to heat and deterioration, and ability to hold up against high-stress conditions. This details is essential in ensuring the security and reliability of airplane.

Future Patterns in Materials Testing

In the world of materials screening, innovations in products evaluating approaches are shaping the trajectory of the area, ushering in a new era of technology and accuracy. One future pattern in materials screening is the combination of synthetic knowledge (AI) and maker knowing algorithms right into testing processes. go right here These methods permit for the assessment of material buildings without creating damage or change to the example, making them perfect for testing irreplaceable or important products.

Final Thought

In conclusion, products testing plays a critical function in various markets by guaranteeing the top quality, security, and efficiency of materials made use of in products and frameworks. It entails evaluating a vast array of products using different techniques and devices to review their mechanical, physical, and chemical residential properties. The results acquired from products testing are utilized to make enlightened decisions in material layout, option, and production procedures. As technology advancements, materials checking laboratories will certainly remain to adapt and enhance check these guys out their techniques to fulfill the evolving needs of markets.

Via a mix of innovative strategies and specific devices, materials test laboratories are able to analyze the properties of steels, polymers, compounds, and other materials under various problems and stress factors. By carrying out tests on materials like wood, steel, and concrete, they can ensure that these products satisfy the required criteria and can hold up against different environmental problems.

In the aerospace market, materials examination outcomes are important in determining the viability of materials for airplane elements. By evaluating products for additional resources their flexibility, stamina, and resistance to effect, manufacturers can pick the most appropriate products for different auto elements, such as body panels, engine parts, and security features.In the world of products testing, innovations in materials examining approaches are forming the trajectory of the field, ushering in a brand-new age of development and accuracy.